Product introduction

Hot rolling generally refers to the rolling of metal above the crystallization temperature. Compared with the common cast and rolled products, the hot-rolled aluminum plate has the characteristics of good surface quality, strong mechanical properties and ductility, and good oxidation effect. The hot-rolled aluminum sheet produced by Xinyu aluminum industry not only has a more smooth and delicate surface, good deep drawing and oxidation effect, but also has a width of 2650mm. It is one of the few manufacturers that can produce ultra wide aluminum sheet in China. At present, the hot-rolled aluminum sheet produced by Xinyu aluminum industry is widely used in wide curtain wall plate, automobile, ship, bus, silo, stamping parts, mold and other fields.:

The difference between hot rolled aluminum sheet and cast rolled aluminum sheet (also called cold rolled aluminum sheet)::

The difference between hot-rolled aluminum sheet and Cast-rolled aluminum sheet (also called cold-rolled aluminum sheet) cold-rolled aluminum sheet is also called Cast-rolled aluminum sheet. The difference between cold-rolled aluminum sheet and hot-rolled aluminum sheet is from six aspects: price, billet supply, production process, performance, use and finished product. :

1、Price: the process of cold rolling aluminum sheet is simple, and the price is cheaper than that of hot rolling aluminum sheet. :

2、Different billet supply: the difference between the two lies in the different billet supply. :

Hot rolled material: aluminum ingot -- melted and cast into flat ingot -- milled surface -- homogenized annealing -- hot rolled into plate and strip:

Cast rolling stock: aluminum ingot -- smelting -- rolling into plate and strip through casting mill. :

Compared with hot rolling stock, cast rolling stock has high production efficiency, but defects such as composition segregation and inclusion are not easy to solve, and its quality is not as good as hot rolling stock. :

3、The production process is different: cold rolling is made by the cold rolling mill to produce the cast coil (8mm thickness), and hot rolling is made by the hot rolling mill to heat the aluminum plate ingot (400-500mm thickness).

4、Different properties: the surface quality of hot-rolled aluminum plate is good, the mechanical properties and ductility are strong, and the oxidation effect is good.

5、Different uses, cold-rolled aluminum plate is mostly used for mold, hot-rolled aluminum plate is suitable for stamping and drawing.

6、Product difference: generally, the elongation of cold rolled products is lower than that of hot rolled products.

The hot-rolled aluminum sheet produced by Xinyu aluminum industry is widely used in wide curtain wall plate, automobile, ship, bus, silo, stamping parts, mold and other fields.

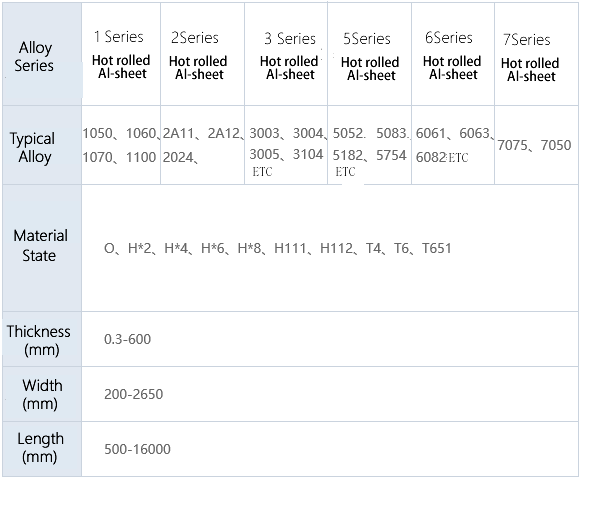

Technical parameter

Technical equipment

The main production equipment of the plate and strip branch of the group company: 41 casting mills, 7 cold rolling mills, 1 double coiling hot rolling mill, 2 semi continuous casting machines, 5 stretch bending straightening machines, 25 annealing furnaces, 8 cross cutting machines, 3 slitting machines and 2 on-line annealing washers.