Product introduction

7075 aluminum bar is a cold-treated forging alloy with high strength, far superior to mild steel. 7075 aluminum bar is one of the most powerful commercial alloys. General corrosion resistance, good mechanical properties and anode reaction. The fine grains make the deep drilling performance better, the tool wear resistance enhanced, and the thread rolling more distinctive. Zinc is the main alloy element in 7075 aluminum bar. Adding magnesium to the alloy containing 3% - 7.5% zinc can form mgzn2 with remarkable strengthening effect, which makes the heat treatment effect of the alloy much better than that of aluminum zinc binary alloy. With the increase of zinc and magnesium content in the alloy, the tensile strength will be further improved, but the resistance to stress corrosion and exfoliation corrosion will be reduced. After heat treatment, it can achieve very high strength characteristics. 7075 aluminum bar materials are generally added with a small amount of copper, chromium and other alloys. Among them, 7075-T651 aluminum bar is particularly superior. It is known as the best product in aluminum alloy, with high strength and far superior to any mild steel. The alloy has good mechanical properties and anode reaction. Representative applications include aerospace, mold processing, mechanical equipment, tooling and fixture, especially for manufacturing aircraft structures and other high stress structures with high strength and corrosion resistance.

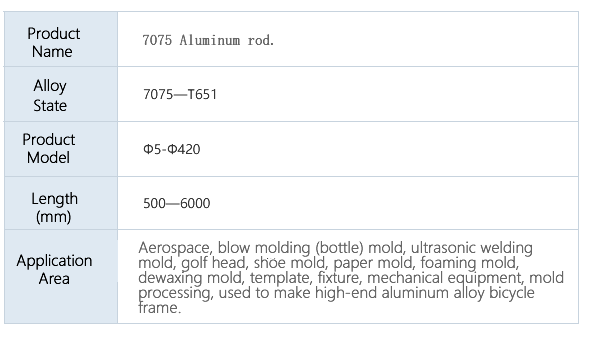

Technical parameter

Technical equipment

The extrusion branch of the group company has four Taiwan extruders of different tonnage, two T6 aging furnaces with six channel constant temperature, four mould heating furnaces and four round bar straighteners.