Product introduction

5A05 aluminum bar is an aluminum alloy of Al Mg system, with strength equivalent to 5A03, which can not be strengthened by heat treatment; it has high plasticity in annealed state and medium plasticity in semi cold work hardening; it has good welding performance in hydrogen atom welding, spot welding, gas welding and argon arc welding; it has high corrosion resistance, poor machinability in annealing state and good machinability in semi cold work hardening, so it needs to be anodized when making rivets.

Al-Mn alloy is the most widely used aluminum alloy with many valuable characteristics. :

1、This alloy has high strength, especially fatigue strength ;

2、High plasticity and corrosion resistance, can not be strengthened by heat treatment, good plasticity in semi cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, poor machinability and polishing.

3、It is mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other small load parts made by deep drawing: wire rod is used for rivets.

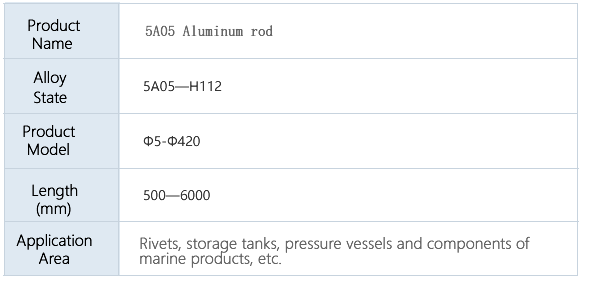

Technical parameter

Technical equipment

The extrusion branch of the group company has four Taiwan extruders of different tonnage, two T6 aging furnaces with six channel constant temperature, four mould heating furnaces and four round bar straighteners.